Winterthur, April 2021 – Highly automated production environments such as those now prevalent in the automotive industry require precise, resource-efficient assembly processes with ever-shorter cycle times. The NCFH joining system from Kistler is the environment-conscious solution that ensures high standards of quality, throughput and cost efficiency.

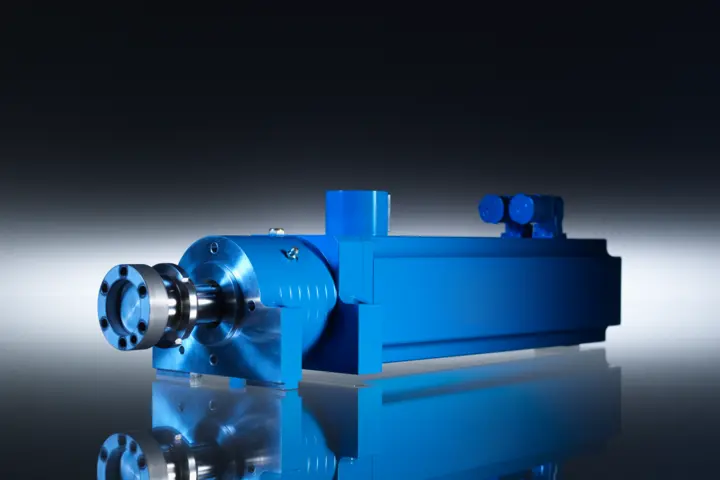

Electromechanical joining systems from Kistler are increasingly the solution of choice for press-fit processes to join parts in many industries including the automotive sector. As a scientific study already showed back in 2012, they save many times more energy than hydraulic and pneumatic systems. They also offer other benefits: the applied force is developed precisely, and continuous monitoring ensures that damage to parts is avoided throughout the process – especially when cycle times are short. These reasons explain why NC joining systems from Kistler (NC: Numeric Control) are usually amortized within a short period – and they also help to maintain a better CO2 balance.