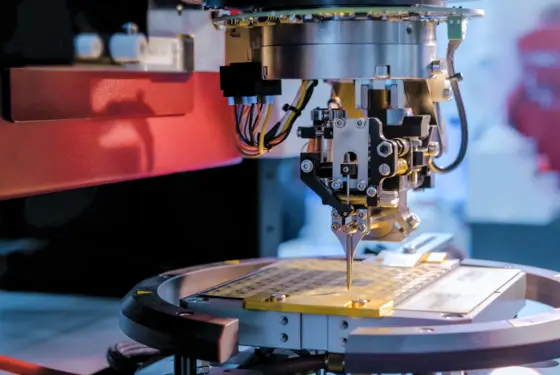

Semiconductors are not all developed with the same requirements in mind: While AI microchips for smartphones need to be as small and powerful as possible, power semiconductors for cars need to be able to function at extreme temperatures and last for a long time. No matter what they are used for, producing them is increasingly difficult due to miniaturization, new materials and production processes.

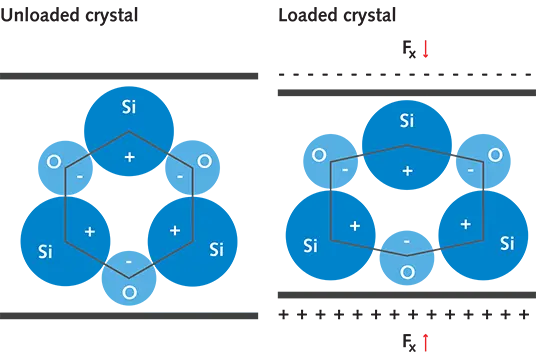

One factor that can impact yield is mechanical stress. Caused by semiconductor production processes like grinding, sawing, CMP, bonding, handling and testing mechanical stress can result in fine cracks or other microscopic defects on both wafer and microchip. Dynamic force measurement featuring piezoelectric sensors has proven to be essential for keeping mechanical stress in check. Measuring force is an opportunity for optimization, minimizing the influence of disruptive factors and increasing efficiency without sacrificing the finished microchips’ performance and power. Production processes like bonding need to control force, temperature and displacement.

![Semiconductor manufacturing: how piezoelectric sensors improve quality and yield [object Object]](https://assets.kistler.com.cn/SAPCommerce_Document_Preview/962-084e.webp)